Creasing Matrix: Importance and Various Uses

BNumerous industries make use of various die-cutting techniques to create attractive shapes and designs for their products. A creasing matrix is a piece of equipment frequently used during the die-cutting process. It is a must-have for individuals and businesses. That want to make use of die-cutting for the design or production of goods.

Usually, the matrix is used for crease-forming cardboard during the production process of packaging materials such as boxes or cartons. They are also used for manufacturing different products for numerous niche industries.

Originally, it was made to help with the easy setting-up of die-cutting equipment and machines. As a system, the creasing matrix helps the base self-align with the creasing rule, which, in turn, can allow manufacturers to impart a perfectly rendered crease to a corrugated or solid board.

Previously, the matrix gained popularity, the entire process had to be set up manually, which made manufacturing time taking. This is why it is so important in the modern world, where cost-effectiveness and quick turnaround times are required for companies to stay competitive.

The Importance of a Creasing Matrix

In today’s print finishing industries, the presence of one or more creasing matrices is a must because of the tight deadlines. that the manufacturers often have to deal with. A creasing matrix can ensure the creasing base’ accurate alignment. Thus, reducing the amount of downtime associated with the die-cutting process. And the less downtime that is required, the more efficient the manufacturing process would be.

Creasing a matrix is especially important when working with thicker materials, such as cardboard or plastic. These materials can be difficult to fold without cracking or breaking, which can ruin the final product. The matrix ensures that the crease is precise and uniform, allowing for a clean fold every time.

One can also avail multiple profiles of the creasing matrix. which would enable the creation of creases that are nearer to the cut windows and die-cut edges of the material (mainly cardboard).

This capability of a the matrix, which allows it to quickly locate and align the creasing rule with the base, assures a precise and perfect register between the matrix creasing plate and the die-cutting plate.

Such a precise register, in turn, allows for difficult packaging designs to be made by die-cutting machines. As a result, a better and more durable product can be manufactured. This would not have been possible without the use of the creasing matrix in the die-cutting process.

Benefits Of Creasing Matrix

A significant benefit of creating a matrix is that it can help reduce production time and waste. When using a die-cutting machine, the matrix is inserted into the machine along with the cutting die. Since die-cutting and creasing are two activities that are usually performed at the same time by the same piece of equipment (known as a die-cutting plate).

This allows both the cutting and creasing to be done in a single pass, reducing the need for multiple passes through the machine, which, in turn, can save a lot of time.. Additionally, because the crease is precise, there is less material wasted due to mistakes or incorrect folds.

Different Uses of the Creasing Matrix

Creasing matrix can be used in a variety of industries, including print finishing, packaging, and manufacturing. In print finishing, a crea is used to create precise creases in materials such as paper and cardboard. This is important for creating professional-looking brochures, booklets, and other printed materials that require folding.

Another important use of the matrix is in the creation of specialty items such as greeting cards, printed materials. These items often require intricate folding patterns and shapes. that can be difficult to achieve without the use of a creasing matrix. With the help of the matrix, designers can create unique and eye-catching designs that stand out from the crowd.

The creasing matrix is also important in the world of bookbinding. Books need to be able to open and close easily, without damaging the spine or pages. The matrix allows bookbinders to create precise folds in the cover and pages of a book, ensuring that it will open and close smoothly and without any damage.

In the packaging industry, a creasing matrix is used to create packaging materials such as boxes and cartons. These materials must be folded precisely to ensure that they are sturdy and can hold their shape. Without this matrix, the packaging may not fold correctly, leading to a weaker structure that is more prone to damage during shipping.

A creasing matrix is also used in manufacturing, particularly in the production of products that require folding or bending. For example, a creasing matrix is used in the production of furniture, where precise creases are needed to create a sturdy structure that can be easily assembled.

Setting Up a Creasing Matrix

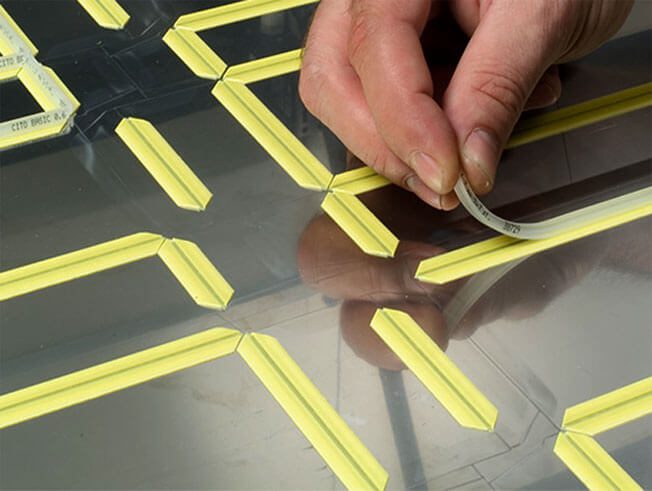

The process of set-up begins when the strip of the creasing matrix is shortened. This is to match the crease rule in the crease pattern. On a die-cutting plate, this trimmed strip is then laid over the many crease rules.

When trimming the matrix to match the length of the rules, the cut at the end should be beveled to a forty-five degree angle. This is to ensure the accurate folding of the material into the corners of all adjacent fold lines.

After the matrix has been properly positioned on the creasing rule, one must remove the adhesive backing tape from the bases of the matrix. It will then be time to set the die-cutting plate in the die press along with the base plate.

Afterwards, the two components must be pressed together to facilitate the transfer of the matrix base onto the base plate. And the automatic self-location feature of the matrix will guarantee a flawless alignment between the creasing channels.

Conclusion

To achieve the desired finish, the buyer must be able to calculate the right creasing matrix, which must be used for any particular card material with a given thickness level. They must also only purchase the matrix from a reputed online or offline seller.